Hey guys,

I am working on a problem which features a strong dependence of temperature and conductivity.

A ceramic heating element is heated through Joule heating. As the ceramic is a PTC, the electrical conductivity increases rapidly once the temperature passes a certain threshold (the so-called Curie-temperature).

I have successfully modeled the behavior of the electrical conductivity in dependence of the temperature through the following function:

R = (T<=T_curie)*R_0 + (T>T_curie)*R_0*(1+(T-T_curie)^Curie_exp)

sigma = 1/R

Bascially, the resistance increases by 10e2 over about 5K, once it goes past T_curie.

The challenge: Once the simulation reaches the point where the resistance is no longer constant, it becomes very unstable. I understand that this is mainly caused by the very strong interaction between

V -> Q -> T -> R -> V

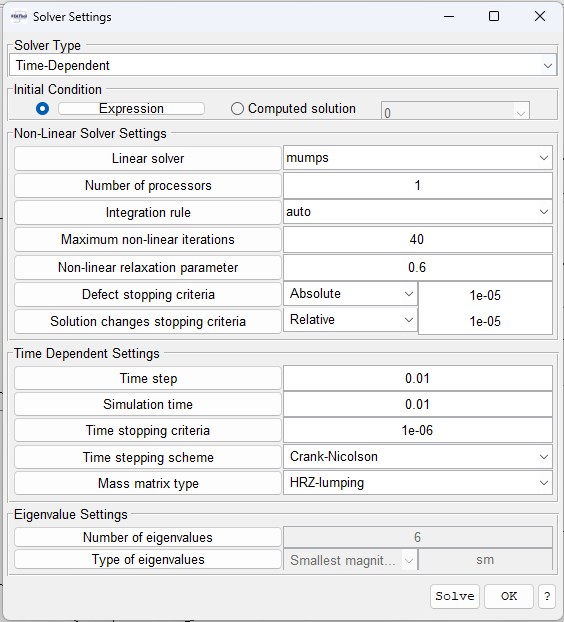

I have been able to tackle this with a high relaxation factor of 0.6 and a timestep of 0.01, but this makes the simulation very slow, especially as the small timestep is not necessary for the part where R stays constant.

Any suggestions on how I could further optimize the solver?

I have read a couple of things about variable time-stepping or relaxation factors decreasing between iterations, but I don't think I can implement those through the GUI.

I would gladly attach the model, but I don't know how to delete the results from the file and with them it is too big. But here are at least the current solver settings.